78

ALRAQABA . ISSUE 15

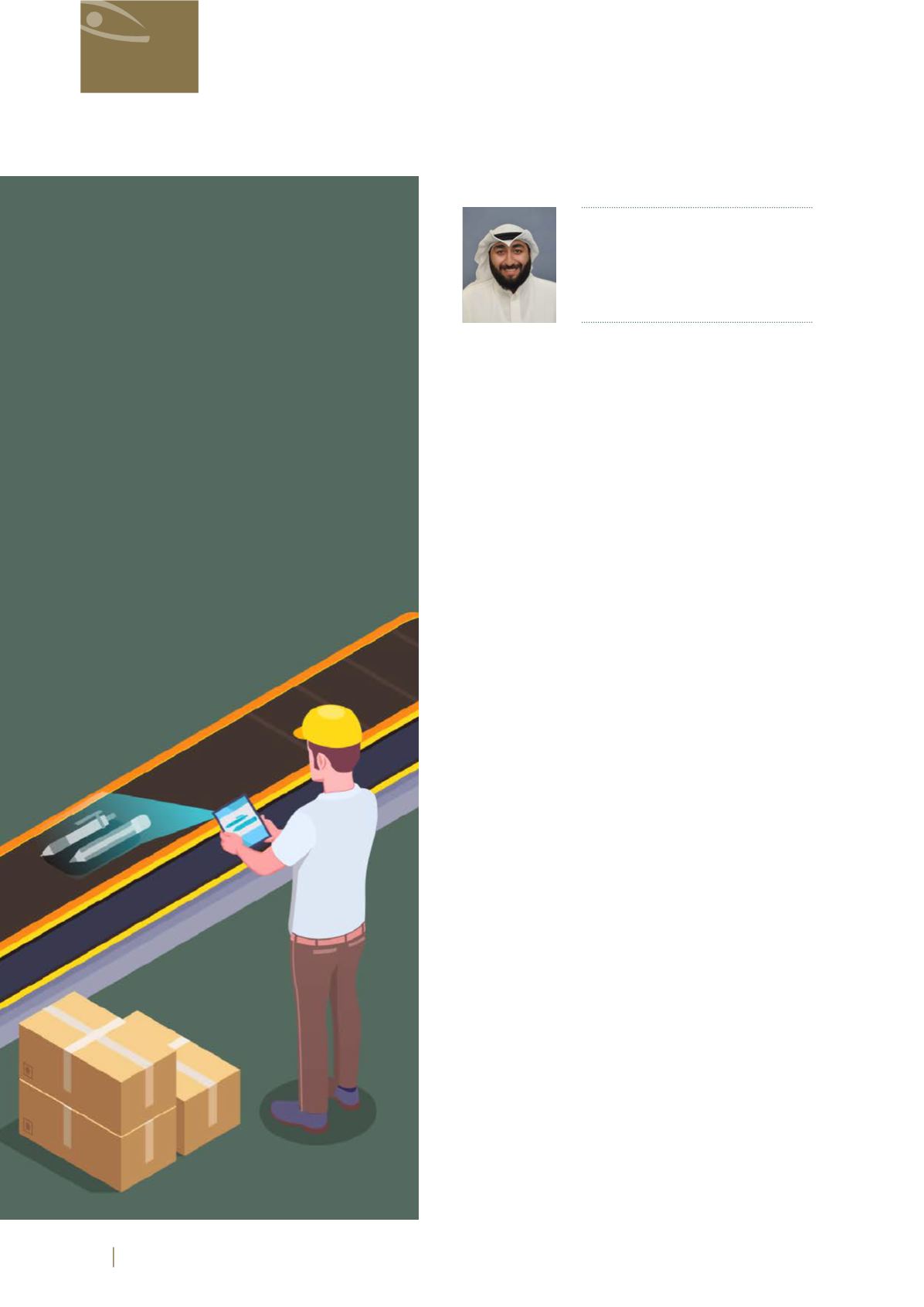

Manufacturing refers to the process of making

products from raw materials using manual

labour or machinery and typically performed

systematically with a division of labour. The

objective of the thesis is to help manufacturing

industries identify potential defects in product

quality as early as possible (even from the first

batch) without additional costs to manufacturing.

Python software was used to create a code (using

an artificial intelligence method called Random

Forest) to help audit the manufacturing process

from a small dataset. From a sample, the code

can predict the quality and performance of the

output with an accuracy of %95–92 (where the

previous accuracy was around %87–82).

The whole idea of the thesis is simple. Consider

a company that manufactures 1,000 pens, where

the defective pens account for about %7–5 of the

whole batch when using current machine learning

methods with different constraints, such as the

data being no less than 10,000 points, which

needs domain experts with a background in data

manipulation and requiring much time to predict,

sometimes more than a year.

Therefore, the author created a new method

called «MRF» to overcome those constraints

with fewer defects of only around %4–2, which

provides a better solution for future manufacturing

by modifying the output quality .

Furthermore, much material is involved in

manufacturing pens (rubber, ink, plastic, etc.).

With the MRF method, the materials can be

modified to increase the pens’ quality with

fewer defects.

Thesis Summary

Manufacturing

Process Causal

Knowledge

Discovery using

a Modified

Random Forest-

based Predictive

Model

Mishari Abdul-majeed Ibrahim

Associate Engineer - Mechanical Engi-

neering Technical Support Division

Theses